It is a generic question when it comes to cars whether Rust proofing or undercoating is essential, or are these processes merely additional car improvements that can be dispensed with.

No one knows the exact answer as each car varies and some may or may not need one or both of these. However, practicality wise, Rust proofing and undercoating are things to keep in mind for a car’s durability.

Back in the old days, the cars were prone to rusting within a few years from manufacture because car coatings were still not technologically advanced. Nowadays, several Rust proofing techniques have been discovered, which help improve the longevity of the car parts. This, however, does not ensure that no more rusting will occur.

Various factors that affect the deterioration of a car’s exterior still exist. These include, primarily, the weather and heavily salted roads. This is why it is important to take into consideration the car itself, its build, model, manufacturer, and the Rust proofing and undercoating already made during the manufacturing of the vehicle.

Car Rust proofing

Rust proofing is a process of delaying or preventing the rusting and corrosion of steel objects including iron, which is limited to surface treatment. The deterioration of such objects may be permanently stopped, provided that the process of Rust proofing is undertaken periodically. However, this is also subject to environmental and other conditions.

If done properly, Rust proofing can last for a maximum of ten years, regardless of the weather conditions. Since rust is a chemical process that can be interfered with, it just takes the proper composition and quality of the product that will be used to counter it. Luckily, there is a wide array of options when it comes to rust proofing.

Electronic Rust Protection Module

One method of Rust proofing is called the electronic module. This comes in a small tool that requires a professional install correctly.

According to Alex Smeall of Reader’s digest Canada, this method works by emitting feeble current through the car’s metal body consisting to prevent corrosion. He further stated that this method often incurs varying reviews from consumers as it is less invasive as compared to other methods. Aside from that, it tends to be more expensive with a price range of $500 up to $1,000.

Further Read: how to stop rust on car

Tar Based Method

Another method is called the tar-based spray or that which is referred to as the “undercoating.” This method can traced back to as far as the 1950s and was used to decrease the noise made by cars.

The tar-based spray, as explained by Smeall, includes the spraying of a tar-like material on the exposed parts of the underside of a vehicle. This substance hardens and serves as a permanent coating against moisture and salt from highways. This method requires yearly inspections and costs around $150.

Dripless Oil Spray and Drip Oil Spray

Lastly, there are the methods of Dripless Oil Spray and Drip Oil Spray. Dripless Oil Spray has similarities with the tar based method where it creates a seal for the vehicle once it hardens to coat against moisture. Compared to the tar-based method, however, the dripless oil shields more parts of the car, and can be applied on its interior parts.

The drip oil spray, on the other hand, has a more tacky consistency than the dripless oil method. This is one of the most recommended methods of Rust proofing as it has better penetration compared to the other Rust proofing methods. It, however, requires yearly reapplication costing $120 to $140.

Car Undercoating

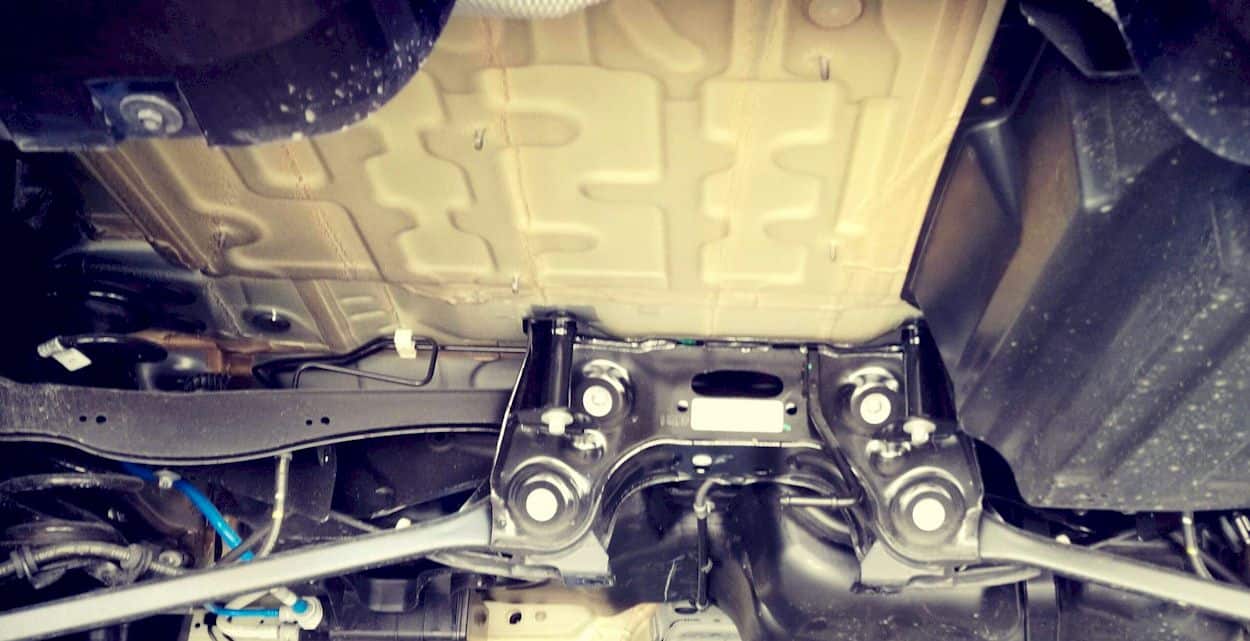

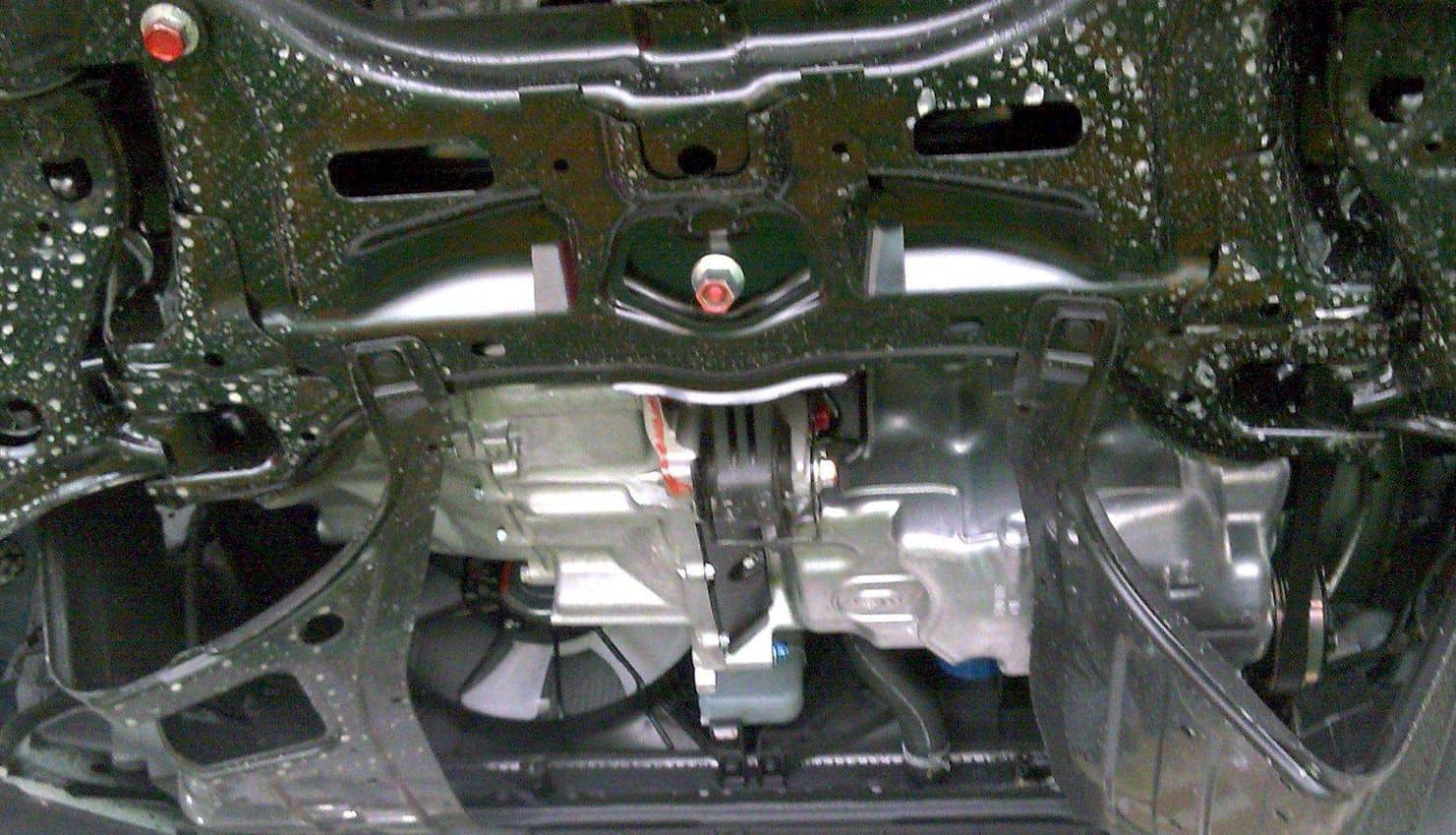

Undercoating is often confused with Rust proofing, with others claiming them to be the same thing. However, while both processes protect the vehicle from rust and corrosion, undercoating focuses more on the underside and chassis of the vehicle.

Undercoating is the application of either rubber-based composite or wax on the entire underside of the car to create a rust-proof layer. It also serves as a means of preventing further damage to vehicles whose underside has been exposed to rust or other contaminants.

Just like Rust proofing, there are also various methods in undercoating a vehicle. Since it is quite expensive to have your car undergo undercoating professionally, most of the methods can be done for a fraction of the price by doing it yourself.

Rubberized Undercoating

One of the methods of undercoating is Rubberized Undercoating, which is primarily used to protect the underside of the vehicle from dents, moisture and dust. It can also be used on quarter panels and wheel wells. That is why it is often the best option for being cost-effective, easy, and simple to apply.

Polyurethane Undercoating

Another method is Polyurethane Undercoating, which includes a polyurethane sealant that makes the process of undercoating a car easier and faster. The method of undercoating generally requires a greater surface preparation as the product would be more effective if applied to well-sanded and etched surface.

Wax Undercoating

Lastly, there is the method of Wax Undercoating, which is the cheapest method in car undercoating. This method, although faster and easier to apply, wears down more easily compared to the other methods. Therefore, it needs more maintenance by being stripped off and reapplied on an annual basis.

How to Apply Rust proofing and Undercoating

After choosing your preferred Rust proofing and undercoating method, it is time to prepare the work station where you will do these processes. It is advisable to have a well-ventilated and clean area.

If you intend to do this outdoors, make sure that the humidity is low and ensure that the area is free of dust and any other debris. You will also need a dust mask and some working clothes.

The first step is removing the rust completely from the vehicle, both on the surface and its underside. This may be done by sandblasting or sanding the areas that have rust. Once done, rinse these areas to remove any other contaminants.

Next is applying the products for Rust proofing and undercoating. Depending on the selected method, most of these products can be applied using a spray gun. It is advisable to use a disposable spray gun since these products harden and become very difficult to remove.

In applying the products, it is best to let the coating dry first before applying the second one. It is advisable to put two coatings to achieve maximum protection for your vehicle. After letting the last coating dry overnight, you can then drive your car on the road, now fully protected.

References:

Alex Smeall, Reader’s Digest Canada

https://www.readersdigest.ca/cars/maintenance/rust-proofing-methods/

National Academics of Sciences Engineering Medicine

https://www.nap.edu/read/13032/chapter/3#12

Bob Weber, Chicago Tribune

https://www.chicagotribune.com/news/ct-xpm-2001-11-26-0111260187-story.html

James is a certified auto technician specializing in commercial vehicles. With 30 years of experience under his belt, James has encountered almost every type of automotive issue there is! Besides his day job at the repair shop, he is also an amateur race car driver.

Wow Thanks for this write-up i find it hard to find excellent ideas out there when it comes to this subject material thank for the information site