Raise your hands if the grinding noise that screams in your ear when you try to start your car pisses you off? Well, I’m sure you raised your hands. Don’t worry; I did too! It’s okay to detest that screechy grinding sound that steals the silence in the atmosphere when you or your neighbor tries to start their car.

Trust me, it’s not normal, and you can silence it permanently. The easiest way to silence it is to shim the starter, and here’s why. Your car makes those grinding noises when you try to start it because the clearance between the starter and the Shim isn’t enough. But with starter shims, you can get rid of the grinding noise and even end the reign that makes it difficult for you to start your car.

How to know if the starter needs shims

If you’re a hobbyist or a PRO at car stuff, you won’t have a problem deciding if your starter already needs a shim. But for those who aren’t familiar with how vehicles work, there are two ways to decide whether or not your car starters need to be shimmed. The first sign is that you’ll realize you can’t start your car without the annoying grinding noise.

Every time you hit the starter, the noise could hit the atmosphere and go on for a while till your car starts. However, when your car refuses to start, another problem could be responsible for it. Also, your car stalls before it starts, or it won’t start at all.

So, before you assume that the starter shim is why your car refuses to start, you should consult your mechanic first. Have him check out your vehicle and its engine to be sure it’s all in good shape. However, the lack of Shim in your starter is primarily responsible for the near-deafening grinding sound or cranks.

Other times, it’s probably because of the space between your starter and flywheel teeth. For instance, when the distance between the flywheel teeth and your starter is too small or too far, your car would get cranky that it starts to make those unpleasant moody sounds. Another possible reason for vehicle crank noise when you start your vehicle is when your mounting bolt is loose.

So, the next time your car lets out a loud screech-like or grinding sound when you try to start it, observe the vehicle for a couple of days. If it’s just a one-time thing, then you might not need to worry too much about fixing anything in the car. However, if it’s consistent, you should take it to the mechanic.

If you know your way around diagnosing vehicles and fixing them, feel free to check the car for diagnosis. If the Shim is the problem, go on to fix it. However, if you’re only skilled at diagnosis but don’t know how to shim a car starter, keep reading. We’ve provided step-by-step instructions on Shim your car starter, regardless of the car you drive.

Related: bad starter sound

How to shim a car starter

Shimming a car starter is one surefire way to silence forever the disturbing crank noise your car makes. But the fact that using a shim quiets the noise doesn’t change that not everyone enjoys using a shim. Nevertheless, you want to deploy a shim; that’s why you’re here in the first place. So, that’s what I’ll teach you. Sit tight as we dig into this topic.

For starters, there seem to be different shim installations for various cars, especially for Chevy cars. Nevertheless, I’ll show you how the manufacturers instructed that you install your Shim. Keep reading.

Disconnect necessary cables

The negative battery cable needs to be disconnected, for starters, so you’ll easily do what you need to do.

Deploy jack stand

Next, you’ll have to raise the car to grant you passage to the part you will install the starter shims. You’ll need stable and good jack stands to help you hold up the weight of the car. While balancing the car on the jack stand, you have to be careful to prevent ugly accidents. Feel free to ask a neighbor or someone for help in setting the vehicle on the jack stand. You do not want the car to slip off the jack stand and close in on you while you’re installing the starter shims.

Inspect the flywheel and the flywheel teeth

Having the Flywheel and the Flywheel teeth is crucial to your car. So, you should inspect the Flywheel and its teeth to ensure it’s still in good condition. If it’s in good condition, then you don’t need to change it. However, if it’s terrible, now would be a good time to replace it. To inspect the Flywheel and its teeth, deploy turning tools. You’ll easily scan the Flywheel to ensure no damage has been done to it.

Related: Bad Flywheel Symptoms

Fit starter pinion and clutch assembly to flywheel

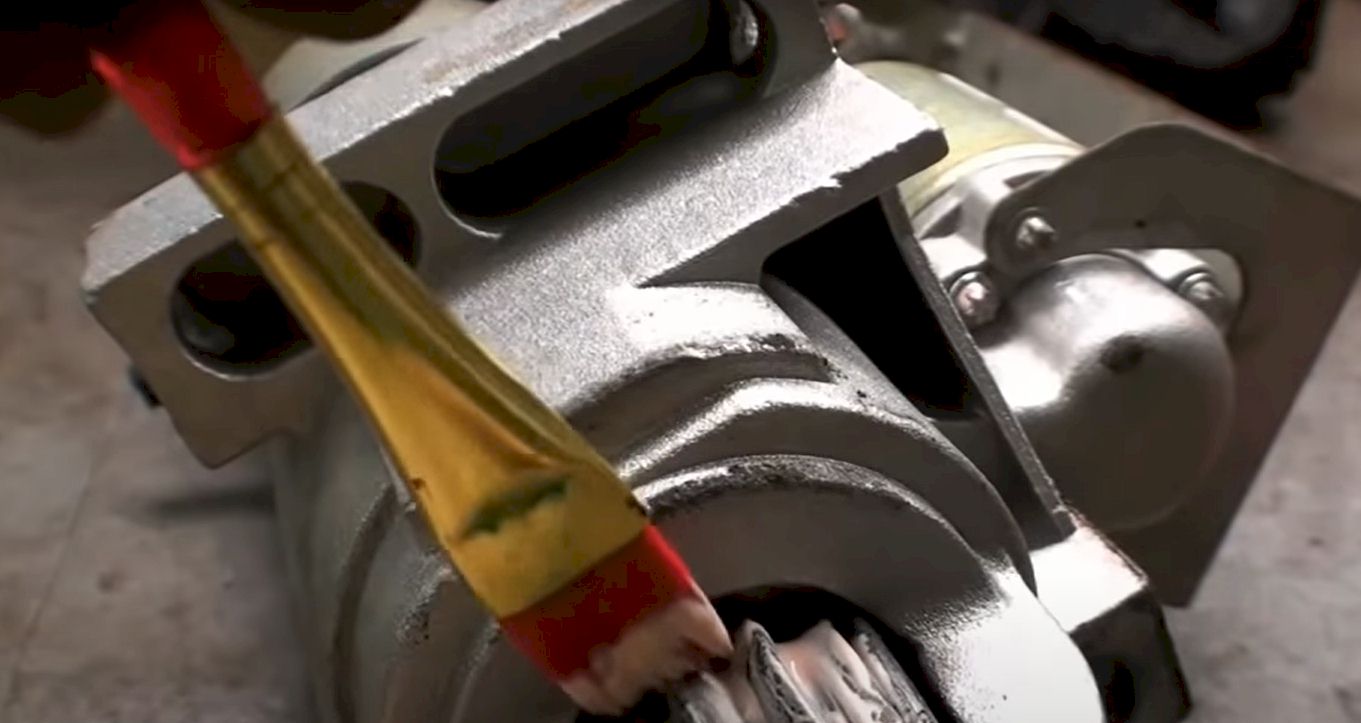

Start by shoving a screwdriver into the hole at the car starter’s bottom. Then, adjust clutch assembly and starter pinion till it is the perfect fit for the flywheel teeth and pinion. You might need to rotate the Flywheel many times to ensure it fits.

Check the clearance

You’ll need a regular wire gauge, spark plug wire gauge, or a 020-inch wire gauge to read the clearance. To do this, the pinion has to sit in the center of the gauge and flywheel teeth to get an accurate reading. Placing it at the corner won’t give you the appropriate reading. To shim your vehicle’s starter from the Flywheel, you simply need to add more shims, but one step at a time. Ensure you check the clearance after adding to the shims.

Wrap up

There you have it! Shimming your car’s starter is not difficult, but it’s still not that simple. You’ll need a bit of expertise and experience to pull it first as you’ll need to do a lot like monitoring the clearance whole installing the Shim. That way, you would control the clearance so that it’s not too much or too small but sufficient to get rid of the annoying car grind song.

Simon graduated with a Mechanical and Electrical Engineering Degree. He has over 20 years of servicing experience in both Japanese and German car dealerships. He now acts as a freelance mechanic’s instructor for local schools.