For people with little to no experience (and patience) in repair work, the first plan of action when facing mechanical defects is to call a mechanic. While we truly know that the mechanics are the unsung heroes of our day-to-day automotive dilemmas, we must not fully rely on them (like your favorite fantasy superhero). Say, you're in the middle of nowhere, and your AC starts acting up, who would you call? You heard it right – yourself.

Be your mechanic of the day and learn the basics of manually engaging your AC compressor clutch. Don't worry, and we have everything explained as less “mechanical” as possible.

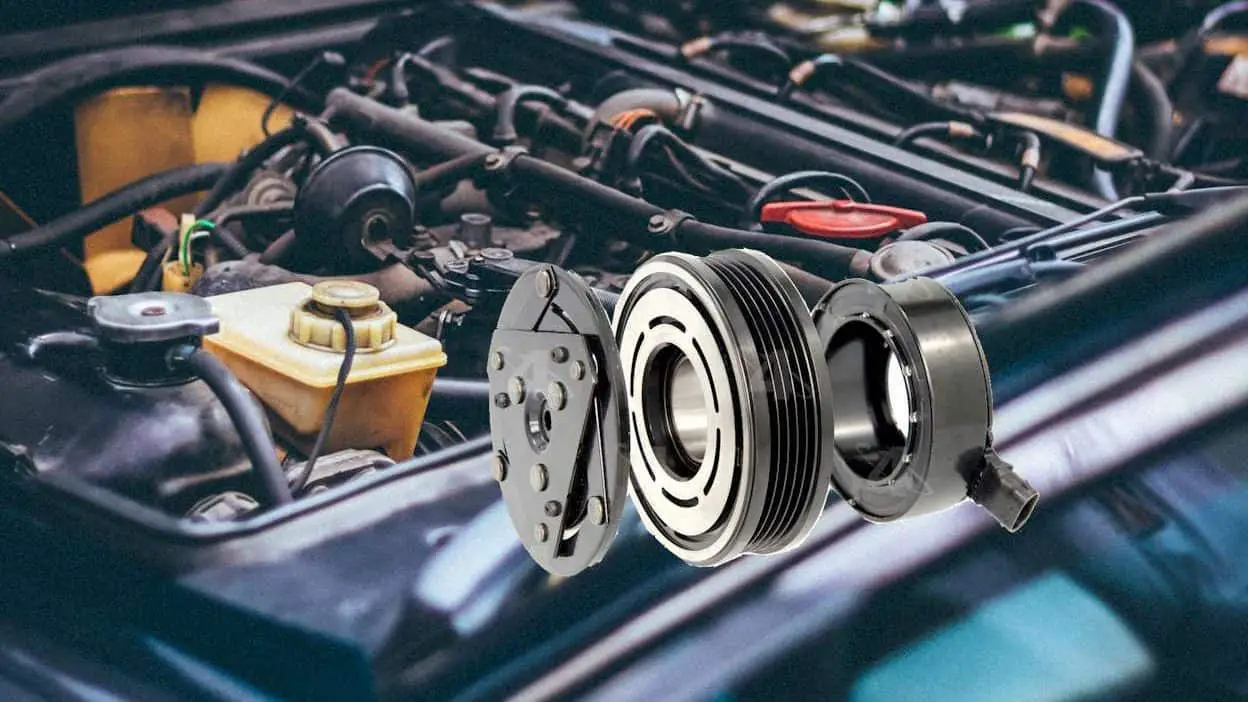

What is an AC Compressor Clutch?

The AC compressor clutch is the first thing that moves every time you turn on your AC. Think of it as a switch that is responsible for engaging and disengaging the AC compressor pulley from its compressor drive.

How does an AC Compressor Clutch Work?

Whether the clutch operates or not will all depend on the AC itself. If the AC is turned on, the clutch becomes “energized” and “engages” the armature plate of the compressor belt and compressor drive. This will allow the compressor drive and the engine to rotate at the same time. Hence, the AC starts working.

On the other hand, a “de-energized” clutch will “disengage” the compressor drive and the belt pulley. This will stop the AC compressor.

Note that we have two main keywords here – “engage” and “energize.” By now, you might be wondering what these two words mean. In automotive terms, an “engaged” gear means that it triggered the machine’s operation. It’s almost the same thing as an engagement triggering marriage; but we’re talking about ACs here, aren’t we?

Going back, our second keyword is “energized.” When a gear becomes “energized,” it is connected to its power source. Think of it the same way as you insert the TV plug into a convenience outlet if you want to watch TV.

What causes an AC compressor clutch to stop working?

Now that you’ve had an idea on how the AC compressor clutch works, let's get straight down to business. Since our main goal here is to engage the clutch manually, we must know what causes an AC compressor clutch to be faulty. Here are three reasons why:

Reason 1: A blown clutch fuse

By far, this is the most common. You must use a multimeter to check for this.

Reason 2: A defective clutch relay

To check this, unplug the connector at the clutch coil and turn on your AC. Then, examine its battery voltage.

Reason 3: The AC has too low pressure

This could also mean a lower amount of refrigerant. This makes the AC compressor to run on little oil, which will result in a defective clutch.

What are the symptoms of a defective AC compressor clutch?

Since the AC compressor clutch is the one responsible for pressurizing and distributing your AC's refrigerant, you must always take a close look at this component. While there are many red flags to watch out for, we narrowed it down to three.

Symptom 1: AC compressor clutch won’t engage

An improper air gap or bad clutch oil may cause this problem.

Symptom 2: AC compressor clutch screeches

Again, it can be due to improper air gaps or rust accumulation in the clutch plate and pulley.

Symptom 3: AC blows warm air

There’s only one reason for this: a slipping clutch. As a result, your AC can’t provide the highest level of refrigerant compression.

Also Read: What Temp Should Air Be Coming Out of Car Vents?

How to Manually Engage AC Compressor Clutch

With all the automotive jargons we’ve discussed earlier, you might think that learning how to manually engage the AC compressor clutch is true rocket science. The good news is – it’s not. Here, we have simplified three methods of engaging an AC compressor clutch all by yourself.

Method 1: You can add more coolant

As what we’ve mentioned before, one of the most common reasons for disengaging ACs is a low amount of refrigerant. How do you solve this? Simply add more coolant. If your AC is compatible with an R134a refrigerant, attaching it to your unit will overrule the low-pressure switch. This will result to a normalized function of your AC compressor clutch.

Method 2: Jump-start your clutch

If your AC isn’t compatible with the R134a type and is actually an older model, consider jump-starting your clutch. This process will only take a few minutes if your AC compressor has enough oil.

Now that we’re talking about oil, here’s a quick disclaimer: Always make sure that your AC is well fed with oil before doing any repairing. Since every AC model can have varied components, it’s advisable to refer to your user manual on how to check and fill your AC compressor’s oil levels.

How do you jump-start your clutch? You only have to do three steps here. First, unplug the wire connector on the compressor’s front side. Second, connect the fused jumper to the same side where you unplugged your wire connector. Remember that it must also be connected to your AC compressor. Third, attach the other end of the fused jumper to the battery’s positive terminal.

Since this method is all about supplying energy to the AC compressor clutch through the battery, no switches are needed for this to work. Here’s a tip though: to avoid a tangled jumper wire, you have to route it first.

Method 3: Replace your clutch

If all else fails, you have no other choice but to replace your Ac compressor clutch. This kind of contradicts with our main goal here, which is to resurrect the clutch.

However, we’re all about immediate solutions here. You have to replace an un-repairable AC compressor clutch right away to keep it from bringing any further damage to your unit.

Additional Reading: Common car air conditioner problems

You may also interest on common car air conditioner problems, the usual causes, and ways to diagnose them. Please read it.

Our Advice

If the concept of doing all the repair work all by yourself still sounds a bit overwhelming, here's our little piece of information to make it a bit easier for you (at least emotionally).

Start with the more straightforward solutions first – that is, carefully checking your AC compressor clutch and going back to method 1.

We understand – you might find all of these enjoyable. However, try not to go too far, experimenting with preventing further damage. If you still can't manually engage your AC compressor clutch, a deeper problem that needs the expertise of a mechanic might be your best bet.

Simon graduated with a Mechanical and Electrical Engineering Degree. He has over 20 years of servicing experience in both Japanese and German car dealerships. He now acts as a freelance mechanic’s instructor for local schools.

I have read so many articles about the blogger lovers however this article is actually a fastidious piece of writing,

keep it up.

Thanks for the review about ac compressor clutch problems. This guide will help to know how too engage or disengage such.

The ac compressor clutch problems can be of any of the ones listed here, and the main reason of this review is to know what’s wrong and if you can fix is okay but if not, dont cause more damage. Visit a professional please

How to jump ac compressor clutch is a great tip for every car owner. It’s easy and straightforward, all thanks to you guys👍

If you have experienced ac clutch engages and disengages before, you will know the benefits attached to this post. Thanks for this guiding post.

Knowing the main cause of ac compressor clutch problems enables us to know how to fix it..I’m a kind of guy who calls a mechanic at the drop of the hat if my car or anything in my car is acting up..and that cost money..knowing how to rectify the faults saves you a bucket load of cash…thanks a bunch for posting this educative piece

I’m not great when it comes to repair my car problems, but it’s always good to learn, ’cause as you said one day I may not find anyone around to help me. Your post was very clear and helped me to understand more about the ac compressor clutch problems.

Thanks for the detailed explanation on how to jump ac compressor clutch. Should I ever get stranded in the middle of nowhere now I know what to do 🙂

Looks like there are many possible causes as to why ac compressor clutch won’t engage. You’ve done a good job explaining every possible cause and how to fix them.

This is the perfect guide for anyone with ac compressor clutch problems. Very detailed and well researched indeed.

I think an ac compressor clutch always engaged can also be a problem. It could really drain the car of its power.

From the article I can gather that whenever ac clutch engages and disengages that’s when the AC works or stops doing so. Great to have at least learnt something new 🙂

Initially I thought this article would be too technical for me. However I’m glad I have actually gained some knowledge on how to jump ac compressor clutch.

If the ac compressor clutch won’t engage it could usually be a sign of a deeper underlying problem. It’s always a good idea to have the car checked in such a situation.

I am happy with how your article tackles ac compressor clutch problems. With this guide anyone should be able to do some basic repairs on their AC systems.

I never knew that learning how to jump ac compressor clutch was so easy. I honestly wish I had seen this write-up much earlier.

Many a times I have found myself in the situation in which ac compressor clutch won’t engage. I will definitely be better prepared next time this happens thanks to this guide.

AC compressor clutch problems are some of the most common AC issues. Every car owner should be armed with the information presented here in case of an emergency.

Oh my! in as much as you have explained how to change an ac compressor clutch, I do hope i don’t find myself in a situation where I would have ac compressor clutch problems. I think i would just leave it for the mechanics.